Farmers face multiple challenges in today's farming environment. Feeding a growing world population, coping with extreme operating conditions and producing more food on fewer hectares while minimizing environmental impact are just a few examples. These forces drive the need for agricultural innovation, such as precision farming, and generate demand for technologically advanced agricultural equipment. In turn, manufacturers are responding with technology that increases farm productivity along with a more efficient, cleaner-running machine.

Downtime can be costly during planting and harvesting seasons. Knowing the capabilities and limitations of a manufacturer's design is key to reliability during peak seasons. Surviving extended runtime and exposure to contaminants is essential to avoiding downtime. Reliable sealing solutions and designs you can rely on are imperative.

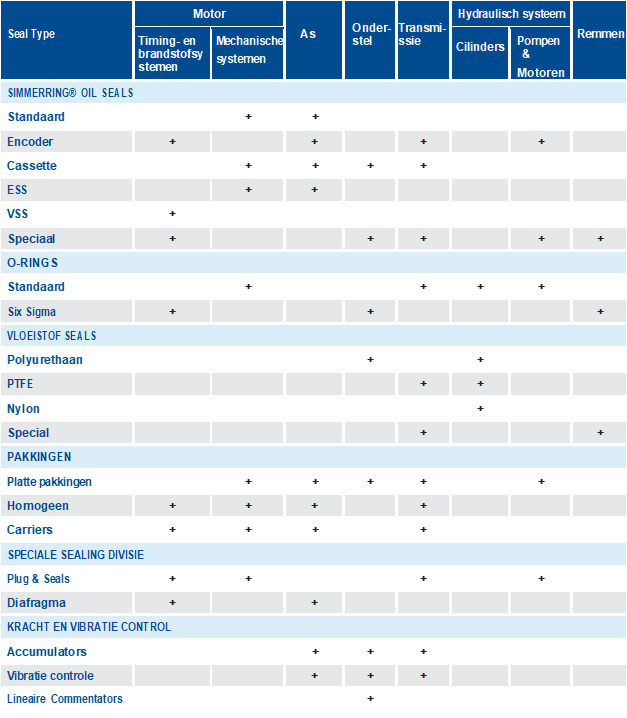

As bot As both a leader and a dynamic innovator in the sealing industry, the global experts at Freudenberg Sealing Technologies provide our customers with the world's largest product range from a single source, along with advanced materials and whether in China or Brazil, farmers across around the world require equipment that can withstand extreme temperatures and provide operator comfort all day, every day. Sealing solutions that reduce equipment vibration promote a smoother, less stressful ride. Innovative sealing components ensure robust operation at temperatures from 250°C to -40°C.

There is no questioning the quality and integrity of your equipment's sealing system, with so many critical agricultural applications relying on sealing technology. Freudenberg Sealing Technologies plows into the future by providing manufacturers with sealing components that combine innovative materials and advanced designs with the latest technology.

manufacturing expertise and revolutionary sealing solutions. We drive innovation with research, development and manufacturing teams integrated into our global operations to meet the demands of global and local markets.

When there is work to be done, downtime is not an option. We help prevent machine breakdowns by providing reliable sealing solutions.

GASKETS

Our gaskets are enhanced for performance through a balance of material and design, providing maximum sealing and durability. Technologies include: homogeneous rubber (press-in-place), carrier type (plastic/metal), embossed rubberized metal, embossed steel, stamped composites, along with high performance alloy materials and secondary coatings.

Custom formulations resistant to biodiesel (fuel systems), aggressive oils (drive systems), coolants (cylinder liners), along with many other fluids, combined with Six Sigma manufacturing capability, transform the average standard O-ring into an integral part of the sealing system.

These precision formed piston seals of hydraulic cylinders provide extreme strength against gap extrusion and high wear resistance. Unique molding techniques provide dimensional stability making it the ultimate seal for tightness and drift resistance for extreme conditions and pressures up to 800 bar.

NEW POLYURETHANE

This superior, cost-effective urethane covers many market needs with one material. AU30000 seals can withstand higher temperatures, higher pressures and more diverse fluids and generally last longer. Ratings of 500 bar and -40°C to 120°C put this urethane in a league of its own.

Freudenberg Sealing Technologies specializes in LESS - Low Emission Sealing Solutions - that reduce friction, improve fuel economy and enable the manufacturer to meet emission standards.

CASCO® SEALS

CASCO generates 70% less friction compared to elastomeric motor seals due to the use of a unique sealing mechanism that takes advantage of centrifugal force. CASCO reduces fuel consumption, contributes to less carbon deposits and is the ultimate long-life seal.

ENCODERS

Accurate and consistent measurement for both cam and crankshaft position at all speeds with no loss of signal quality is provided by our magnetic encoders. They are extremely reliable and can be used to improve fuel economy and thus reduce emissions.

VALVE SEALS

Increase engine efficiency, reduce oil consumption and optimize emissions with our high performance valve stem seals. The special step lip and gas lip are designed to provide additional protection against blowing gas in diesel applications, and the flanged metal housing improves seal retention.

Decades of testing have produced a design standard that utilizes unique materials for consistent performance, low wear, superior fluid resistance, 15 to 20% lower friction, and unique temperature capabilities (-40°C to 175°C) when compared to other conventional competitive seals .

A robust shaft hub seal with multiple exclusion labyrinths built into a single housing, this seal is the ultimate in keeping the elements out and oil in while minimizing friction. The unique design provides excellent contaminant removal at optimized surface speeds.

This is the ultimate seal for increased protection against debris where shaft rotation and end play must be accommodated. Using a unique design that combines scraper elements with seal technology, this seal is proven to extend seal life and reduce warranty claims from the field.

PLUG & SEAL

Plug & Seal is a reliable, tight one piece connector to align components, compensate for misalignment, absorb thermal movement and provide acoustic decoupling. Our high temperature PTFE Plug & Seal version offers durability up to 250°C along with media resistance to almost any fluid.

DIAPHRAGS

High quality and dimensionally stable diaphragms, produced with superior elastomeric materials and thermoplastic polyurethane, can withstand harsh environmental conditions resulting in exceptional seal life. Designs developed by FEA are perfectly matched to the technical requirements, allowing the diaphragms to move precisely.

ACCUMULATORS

Our diaphragm and piston accumulators provide excellent energy storage with unique materials to prevent permeation, cover wide temperature ranges and offer excellent service life. The next generation of lightweight batteries combines the effectiveness of aluminum with the functional capability of a battery to maximize the function/cost ratio.

HYDRO MOUNTS

Hydro mounts / Hydro bushings are a creative solution for driving comfort. A combination of elastomeric materials and hydraulic damping provides optimum acoustic isolation and maximum damping of natural vibrations via internal fluid viscosity and a damping disc. The robust design is optimized for comfort and ensures a long service life.

LINEAR COMPENSATORS

A linear compensator is basically a Freudenberg-designed hydraulic cylinder with integrated piston accumulator that moves suspension designs from spring systems to smooth-running suspension systems, allowing machines to go faster with greater comfort. Systems are custom designed with customer needs in mind.

CENTRAL TIRE INFLATION (CTI)

CTI requires optimized seals that separate gear oil from the air passage used to inflate or deflate tires. Adjusting the pressure improves traction performance, reduces soil compaction, reduces tire wear and improves total cost of ownership. This system reduces downtime associated with tire failures (punctures, etc.).