The materials are available in two different hardness levels to ensure they meet various pressure requirements. Depending on the product and its application area, the most suitable material is selected for the specific use. For metal composite components requiring a strong rubber-to-metal bond, the specially developed 75 Fluoroprene® XP 45 is the ideal choice.

Short Term |

Properties |

Compliant With |

Seal Type |

|||||||||||||

| Color | Temperature Range [°C] | Temperature Range [°F] | Hardness DIN ISO 7619-1 Shore A | EC1935/2004 | USP Chapter 87 | USP Chapter 88 | FDA 21 CFR 117.2600 | 3-A Sanitary | NSF 51 | ADI Free | O-rings | Membranes | Hygienic Usit® | Molded Parts | CNC Machined | |

| 75 Fluoroprene® XP 40 |

|

-15 to +200 | +5 to +392 | A 75 +/-5 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| 75 Fluoroprene® XP 41 |

|

-15 to +200 | +5 to +392 | A 75 +/-5 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 85 Fluoroprene® XP 43 |

|

-15 to +200 | +5 to +392 | A 85 +/-5 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 75 Fluoroprene® XP 45 |

|

-15 to +200 | +5 to +392 | A 75 +/-5 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

Fluoroprene® XP O-rings are renowned for their versatile applications, thanks to both their design and the material they are made from. The broad chemical and thermal resistance of Fluoroprene® XP 41 and Fluoroprene® XP 43, combined with international approvals for use in the food, pharmaceutical, and chemical industries, makes this combination ideal for many critical applications.

As O-rings are a standardized sealing solution, Fluoroprene® XP O-rings are available in sizes compliant with DIN ISO 3601 standards. However, these seals can also be custom-made through our Xpress Service, which provides tailored sealing solutions via precision machining.

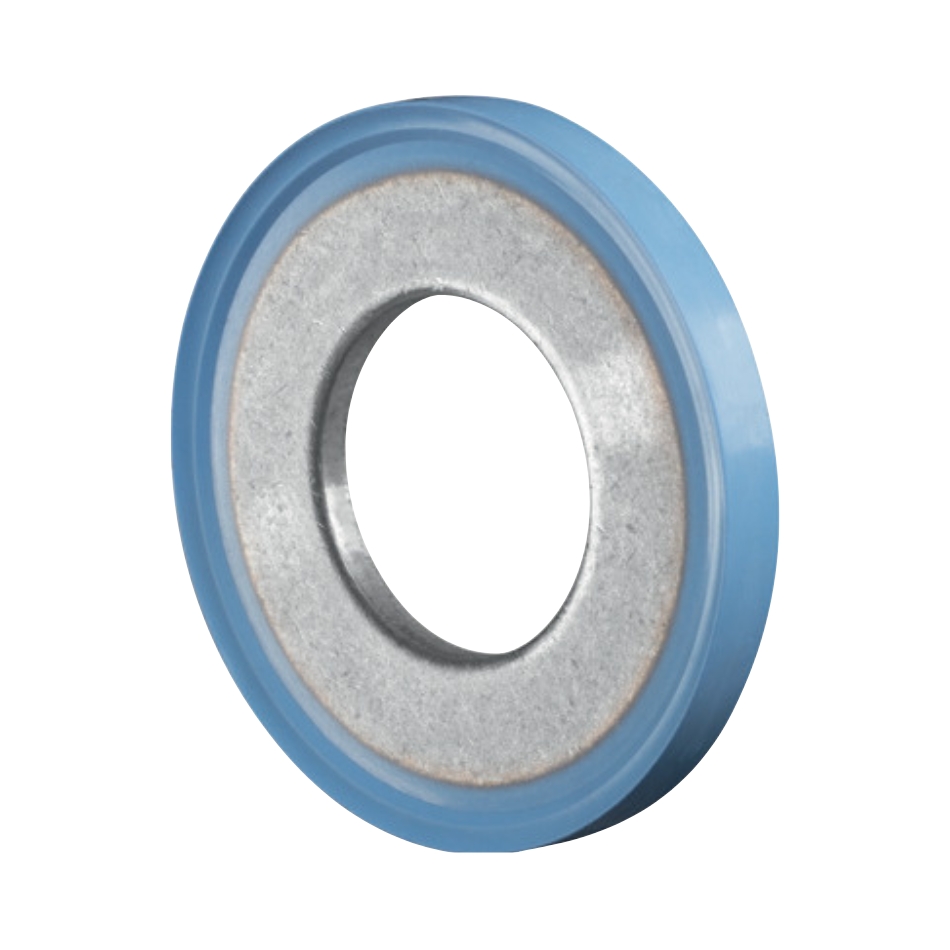

The Fluoroprene® XP Hygienic Usits® from Freudenberg are specifically designed to create a sealed connection for screw joints in or adjacent to product areas, eliminating the formation of so-called dead spaces. The ring with its elastomer layer complies with the design guidelines of Hygienic Design.

The Usit ring features a smooth surface that minimizes adhesion of product residues, making them easy to remove. This helps prevent contamination, such as in the production of pharmaceutical products.

Fluoroprene® XP Hygienic Usits® are available in various sizes, including M4, M5, M6, M8, M10, M12, and M16. Additionally, Kipp, under the NovoNox brand, supplies special hygienic screws and cap nuts that are highly polished, achieving a surface roughness of Ra < 0.8 μm.

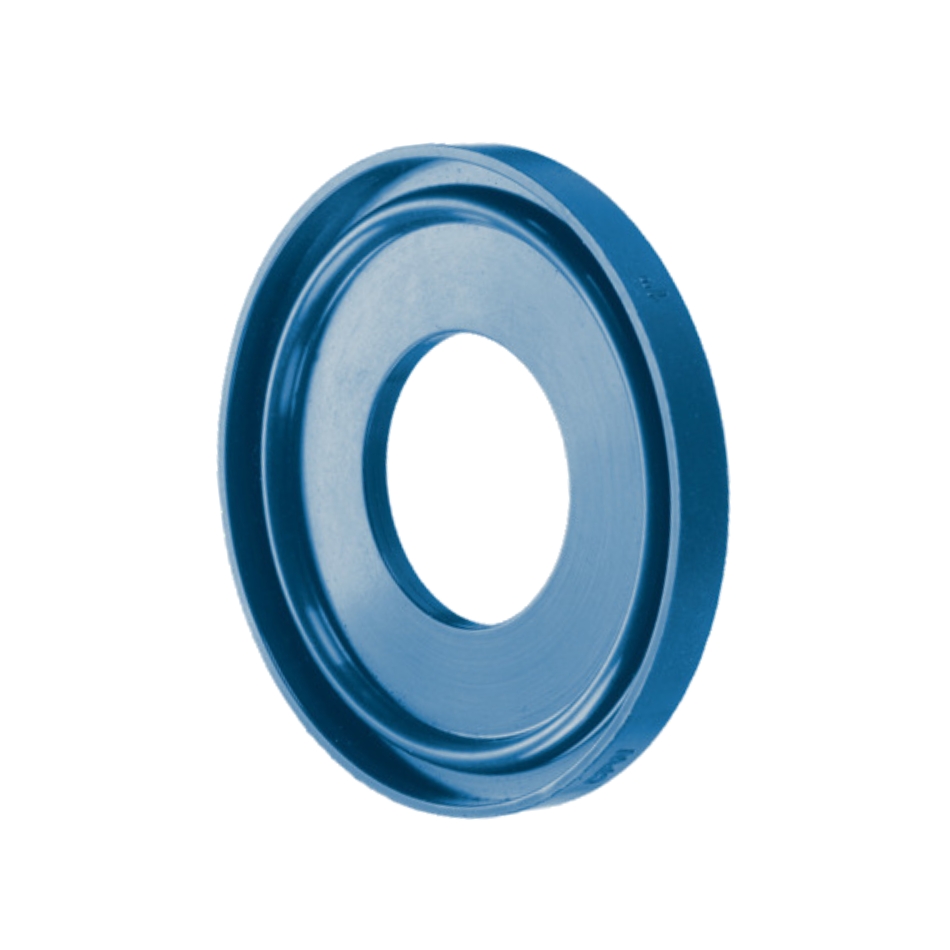

Fluoroprene® XP clamp seals are ideal for critical processes, providing protection in applications within the pharmaceutical and food industries. These clamp seals are used to connect two pipes, adhering to the standardization of DIN 11851 and DIN 32676.

In addition to the clamp seals themselves, O-rings play a crucial role in creating an aseptic clamp connection. The EHEDG recommends using O-rings compliant with the DIN 11864 standard. These seals are designed according to hygienic design principles, ensuring a seal free of dead spaces.

Fluoroprene® XP custom membranes are used to create a tight yet easily movable partition for a confined volume. Since the membrane must be both sealed and flexible, rubber-elastic materials are utilized for this purpose.

In addition to functioning as a partition, membranes can also serve a balancing role, such as in a separator, where horizontal vibrations within the internal section must be balanced against the external part.

The lifespan of Fluoroprene® XP custom membranes can be further enhanced by incorporating fabric reinforcements and foil coatings. This combination allows for the creation of an optimal sealing solution tailored to any application.