Seals for hydrogen applications must combine low permeation, a stable compression set and predictable behaviour under varying loads. In the use phase, thermal cycles, vibration, pressure differentials and strict cleanliness requirements play a bigger role than in many other gas systems. Therefore, we select not only the right product form (O-rings, stack gaskets, seal-on-plate, edge seals) but also compounds and tolerances that demonstrably withstand prolonged cyclic operation. Seals for hydrogen applications only deliver real value when they provide the same leak-tightness after thousands of hours, assembly remains repeatable and performance variation between identical systems is small. This requires material selection based on medium and temperature, design rules that secure compression distribution and measurable criteria for permeation, compression set and outgassing.

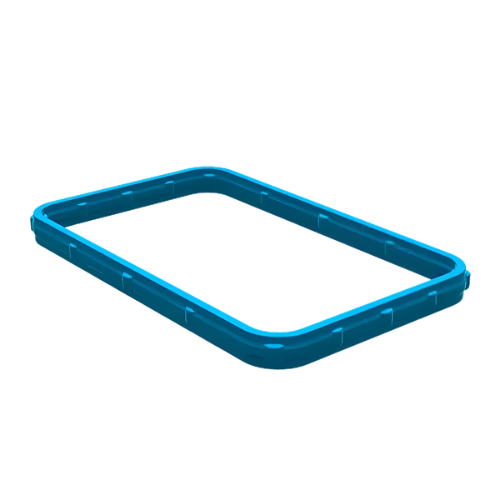

Seals for hydrogen applications must minimise microleakage, because the hydrogen molecule is very small and can diffuse quickly. Low permeation seals combined with uniform compression along the entire sealing line prevent “weeping” and improve the reproducibility of test and operating performance. Uniform compression starts with the right groove geometry, flatness and surface roughness of contact surfaces, plus a hardness that matches the clamping force.

In stacks, an even compression distribution helps not only against leaks but also against performance drift between cells. Seals for hydrogen applications that are compared in identical grooves thus objectively show which design offers the best combination of permeation, compression set and service life.

During use, warm and cold phases, start-stop cycles and mechanical vibration create variable loading. Seals for hydrogen applications must absorb those variations without loss of sealing pressure or dimensional stability. Low outgassing is especially crucial at sensors, membranes and in test setups; here you want to prevent volatile components from disturbing measurements or contaminating sensitive layers. Therefore choose compounds with low extractables and a proven compression set at relevant temperatures. In applications with frequent coupling or switching pressure regulators, it helps to test rebound behaviour and wear explicitly, so that the predicted service life matches practice.

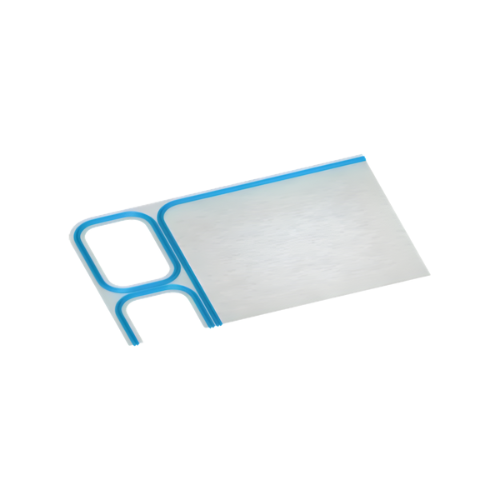

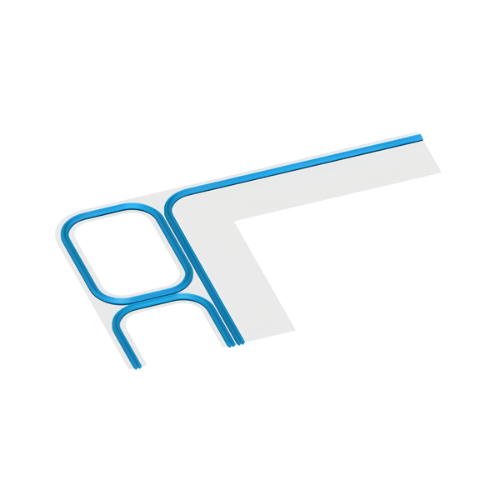

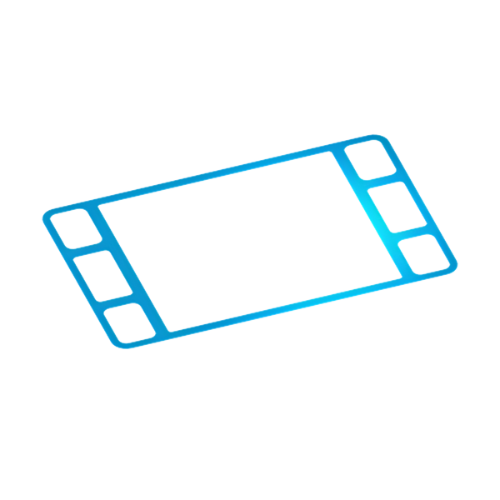

Seals for hydrogen applications in fuel cells require leak-free separation between reactant gases and coolant, plus electrical insulation where needed. Fuel cell seals include bipolar plate seals, GDL edge seals and seal-on-plate/-frame solutions that speed up assembly and secure compression distribution. By combining stack gaskets with ionically clean materials and low outgassing, performance remains stable and contamination of membranes or flow channels is prevented. Seals for hydrogen applications that are specifically matched to the stack geometry reduce variation between cells and increase yield during assembly and test.

Outside the stack, the same principles apply to injectors, sensors, regulators, valves and couplings. Seals for hydrogen applications in these components must compensate for tolerances and lubrication condition, remain leak-tight during pressure switching and withstand vibration. In cooling circuits the focus is on chemical compatibility and thermal stability; at measurement points on low outgassing and stable compression. By selecting the right hardness, geometry and surface specification for each component, sealing pressure is maintained and the risk of microleakage in the field is reduced.

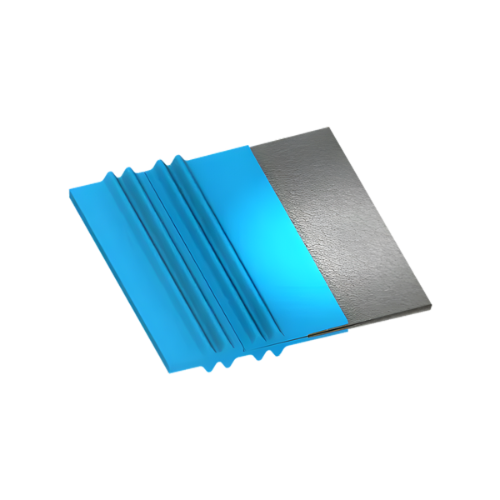

Material selection determines compatibility, service life and cleanliness. EPDM seals are often logical in water/alkali and coolant environments; FKM performs strongly in the 150–200 °C range and with various chemicals, while FFKM provides assurance in extreme chemistry or heat. Where low friction or dimensional stability is essential, PTFE/PEEK elements can provide support without complicating assembly. Seals for hydrogen applications benefit from compounds with low permeation, low compression set and controlled outgassing, especially in stack-adjacent zones and at sensitive sensors. By keeping batches traceable and supplying test data (permeation, compression set, outgassing), validation becomes audit-ready and predictable.

Reproducible performance begins with clear design rules. ISO 3601 groove dimensions ensure comparable compression and assembly conditions across production lines and locations. Also define tolerances, surface roughness and clamping force/torque, so that the compression distribution is uniform and the sealing pressure does not drop during thermal cycles. Seals for hydrogen applications benefit from trial assemblies using the same grooves, loads and temperatures as in the application, so that selection is based not only on material data but also on system behaviour. With large pressure differentials, a supporting element (e.g., a geometric support or back-up) can limit extrusion and extend service life.

In PEM and AEM fuel cells, leak-free gas channels and a stable cooling circuit are decisive for performance and service life. Seals for hydrogen applications in the stack combine low permeation with uniform compression, so that the cells perform consistently and variation remains within tight tolerances. Fuel cell seals with seal-on-plate reduce assembly time and increase reproducibility, while ionically clean compounds and low outgassing protect the integrity of membranes and sensors. By linking design and material selection to the actual operating temperatures and pressure differentials, the predicted service life aligns better with practice.

In hydrogen combustion engines, load, temperature and vibration change rapidly. Therefore, seals for hydrogen applications must withstand shock loads and thermal cycles without loss of sealing pressure. In the fuel path and at control valves, stability during pressure switching is essential; in cooling circuits, EPDM seals often remain the logical choice, while FKM or FFKM can be used at higher temperatures or with more aggressive media. By explicitly specifying component tolerances, surfaces and clamping forces, leak criteria remain achievable and predictable, even after long-term operation.

Volatile substances can contaminate membranes and sensors. Low-outgassing compounds keep measurements stable.

Ensure uniform compression distribution (flatness/roughness/torque) and use suitable stack gaskets. This reduces edge leakage and variation.

Often the best balance with water/alkali coolants. Switch to FKM/FFKM at higher temperatures or with more aggressive media.

Choose vibration-resistant seals with good rebound and keep tolerances tight. This way, sealing pressure is maintained under varying loads.

Compare seals for hydrogen applications in identical grooves under the same temperature and pressure profiles. Combine laboratory tests for permeation and compression set with endurance tests that replicate your cycles.