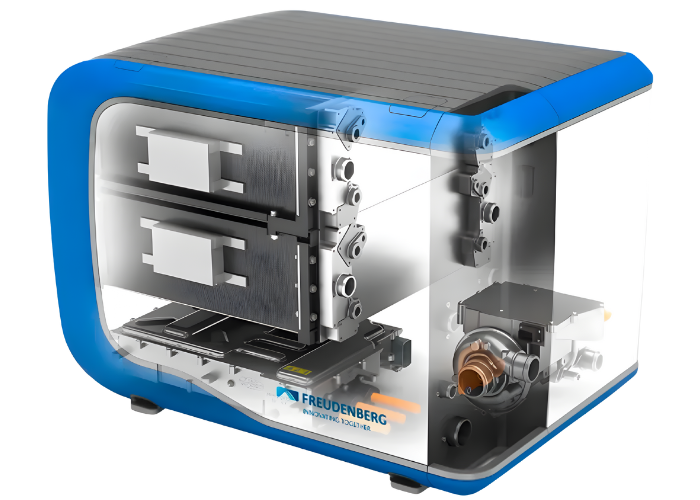

Fuel cells are the heart of the hydrogen economy. They convert hydrogen and oxygen into electricity, with water and heat as the only by-products. The efficiency, safety, and service life of this process largely depend on the quality of the seals. Seals for fuel cells must withstand not only high pressure and temperature, but also the smallest gas molecule that exists: hydrogen. During the use phase of the hydrogen chain, they determine whether a system will operate stably for years or will experience micro-leakage and performance loss. Modern seals for fuel cells combine high chemical resistance with minimal gas permeability, which is essential for stable long-term performance.

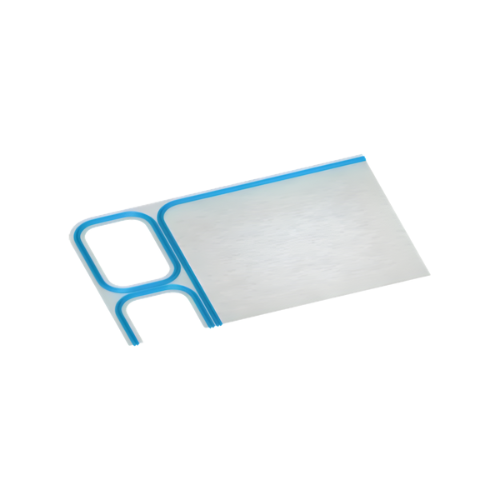

Within a fuel cell stack there are hundreds of cells, each consisting of bipolar plates, gas diffusion layers, and membranes. Seals for fuel cells completely separate hydrogen, oxygen, and coolant from one another and prevent them from mixing. Precision in the production of seals for fuel cells prevents variation in compression, ensuring that every cell in the stack remains optimally sealed. Any leakage affects not only efficiency but also safety. A well-designed seal provides uniform compression across the entire surface and compensates for tolerances between plates and frames. This makes the system more reliable, especially at high pressure differentials and under long-term loads.

Seals perform a dual role: they ensure leak-tightness and contribute to the mechanical stability of the stack. Low-permeation seals for fuel cells limit the loss of hydrogen, preserving the fuel cell’s efficiency. At the same time, the materials must be electrically insulating and resistant to moisture, heat, and chemical exposure. An incorrect choice can lead to leaching of substances that attack the membrane or catalyst. Therefore, hydrogen sealing materials are carefully selected and tested under realistic operating conditions.

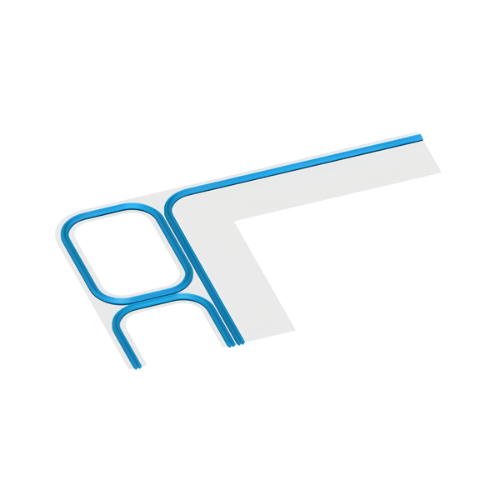

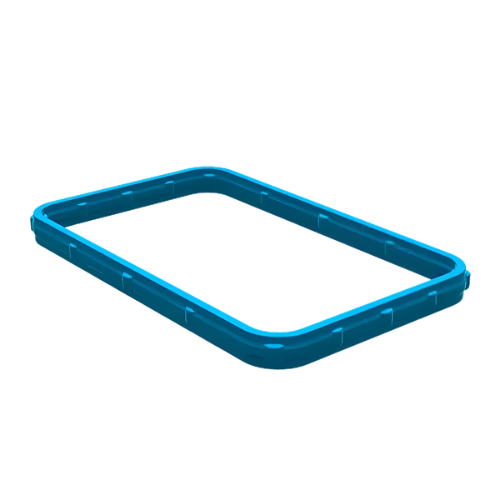

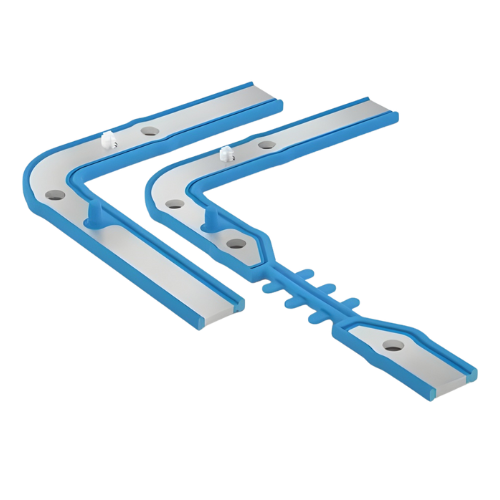

The smallest gas molecules demand the highest leak-tightness. Seals for fuel cells are continuously exposed to varying pressure profiles and temperature fluctuations. Even minimal permeation can lead to efficiency losses or potentially hazardous hydrogen accumulation. Low-permeation seals with controlled compression set provide a solution. Optimized geometry and smooth surfaces keep the sealing pressure stable, even over thousands of cycles. In combination with PTFE back-up rings, extrusion at high pressure is prevented, while ISO 3601 groove dimensions ensure repeatable assembly and compression.

Fuel cells often operate within temperature ranges between –30 °C and +100 °C. The seals must remain flexible during cold starts and retain their shape at continuously high operating temperatures. Seals for fuel cells that withstand these thermal variations show less hardening or cracking over time. Aging is further limited by compounds with a low compression set and controlled vulcanization. Regular inspection of roughness, torque and compression helps prevent leakage at an early stage and extend service life.

The choice of sealing material determines the reliability of the entire system. EPDM seals perform excellently in humid and alkaline environments and retain their elasticity over a wide temperature range. FKM seals, by contrast, offer superior chemical resistance and low gas permeability, ideal for reactive gases and higher temperatures. For the most demanding conditions, FFKM Simriz® seals are used; they combine the chemical inertia of PTFE with the elasticity of rubber. By selecting the right balance between these materials, the seals for fuel cells can perform optimally under pressure and temperature without hardening or swelling.

In zones with high pressure differentials and tight tolerances, design details play a crucial role. PTFE back-up rings protect elastomers against extrusion and deformation while maintaining sealing pressure. Grooves according to ISO 3601 ensure repeatable compression and simplify quality control. Seals for fuel cells operating in gas service are often executed with AED/RGD-resistant O-rings. These compounds prevent internal cracking during rapid decompression, which is essential for safety and stability. A controlled compression set ensures that the seal retains its leak-tightness, even under prolonged cyclic use.

The design of a seal is more than geometry alone. It concerns the interaction between material, surface, and load. A proper compression set ensures a constant sealing pressure, even after thousands of cycles. During validation, seals for fuel cells are tested for leak behavior, aging, and thermal stability. Using simulations and practical tests, it is predicted how the material behaves at high pressure or low temperature. Only seals that meet these requirements guarantee long-term reliability in critical fuel cell applications.

In the use phase of the hydrogen chain, where fuel cells actually deliver energy, the seals must perform consistently both mechanically and chemically. Seals for fuel cells are the key to durability here. In mobility solutions such as trucks or buses, they are exposed to vibrations and thermal shocks, while stationary energy storage involves a constant thermal load. Low-permeation seals prevent fuel loss and contribute to stable performance over thousands of operating hours. By using suitable hydrogen sealing materials with a controlled compression set, leak-tightness is maintained even under repeated loading. In this way, fuel cells deliver not only energy but also reliability at system level.

Because hydrogen is the smallest gas molecule, it can escape through microscopic pores. Low-permeation seals for fuel cells limit this loss, increase efficiency, and improve system safety.

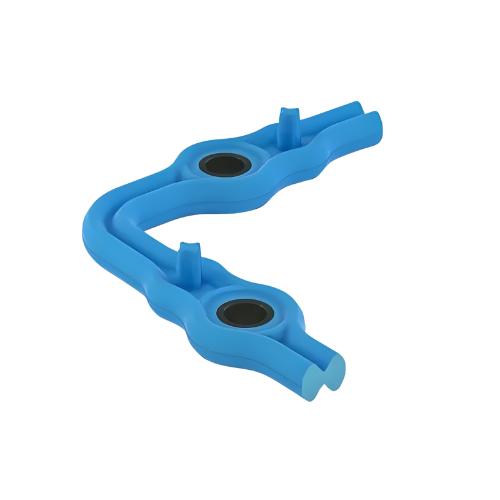

During rapid pressure drops, microcracks can form in elastomers. AED/RGD-resistant O-rings prevent this issue and maintain their sealing force in dynamic gas environments.

At high pressure differentials or larger clearance gaps. They prevent extrusion of the elastomer and ensure that the sealing pressure remains constant during long-term use.

A low compression set means that seals for fuel cells retain their shape after repeated loading. This ensures a stable sealing level and longer maintenance intervals.