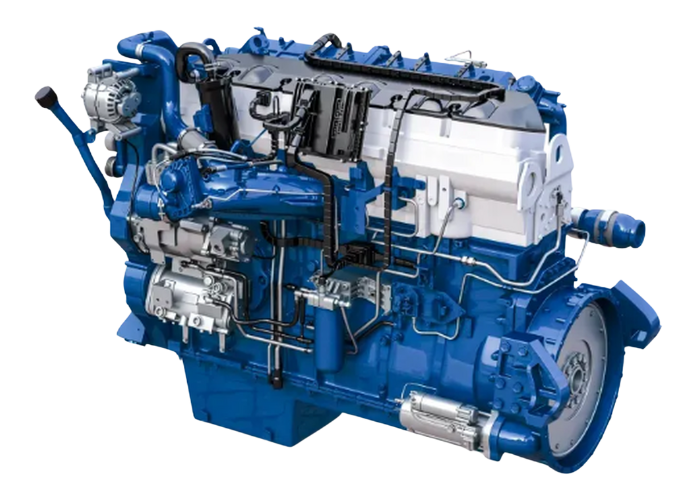

The shift to hydrogen, ammonia, and e-fuels requires a fundamental reassessment of materials technology. Whereas conventional engines ran on oil and diesel, sustainable-fuel engines operate under higher pressures, fluctuating temperatures, and more aggressive media. In this context, Seals for sustainable fuel engines form the quiet core of efficiency and safety. They separate, guide, and protect, and largely determine the service life of engine components. Through intelligent material selection and precision design, the seals make a direct contribution to the energy transition.

The modern engine is evolving toward zero emissions and low maintenance intervals. Seals for sustainable fuel engines play a key role in this, because hydrogen and e-fuels behave differently from fossil fuels. The molecules are smaller, react faster, and can even move through microscopic openings. Due to this high diffusivity, Seals for sustainable fuel engines must withstand gas leakage, pressure fluctuations, and thermal cycles. Whereas conventional engines relied on oil for lubrication, hydrogen engines often run dry or with minimal lubrication.

This requires seals with low friction and high dimensional stability. These seals must move smoothly without extruding or drying out. At the same time, no contamination may occur in the fuel path, since even minute impurities affect combustion. Through precise fit and temperature-stable compounds, these high-grade seals remain reliable, including with fuels such as methanol or ammonia.

The pressure in modern H₂ and e-fuel engines can rise to hundreds of bar, while temperature peaks exceed 200 °C. Seals for sustainable fuel engines therefore have to do more than just seal: they must reduce energy loss, control thermal expansion, and minimize wear. By using elastomers with low compression set and polymers such as PTFE, FKM, or FFKM, this becomes feasible. These materials make the seals stronger, more resilient, and more resistant to rapid pressure changes.

In the crankshaft seal, friction plays a dual role: too little contact causes leakage; too much contact leads to heat build-up. Seals for sustainable fuel engines are therefore designed with optimized lip geometry and controlled pressure distribution. Around valve stems and the valve guide, heat-resistant elastomers provide gas-tight separation between the cylinder and the lubrication chamber. In the fuel system as well, such seals remain critical to keep gas and liquid flows safely separated.

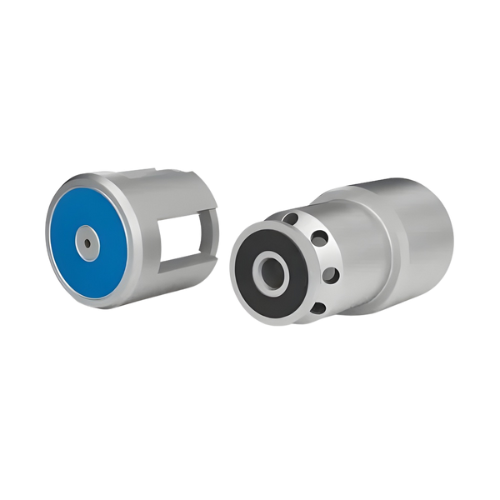

The development of CASCO seals is a breakthrough for Seals for sustainable fuel engines. Their cassette design with axial lip reduces friction by approximately 70 % compared to conventional shaft seals. This extends service life and limits energy loss. Seals for sustainable fuel engines that use Plug & Seal connectors combine sealing and ease of assembly in a single component. They compensate tolerances, damp vibrations, and remain leak-free at high pressure, which is essential in engine blocks with complex geometries.

Valve stem seals are the first line of defense against gas leakage in the upper engine assembly. The seals used here are often made of FKM or a peroxide-cured variant with high thermal stability. Their low permeation prevents “weeping” and loss of combustion gases. Thanks to optimized spring preload, Seals for sustainable fuel engines remain elastic even under prolonged thermal load. The low-permeation seals minimize diffusion and contribute directly to overall efficiency.

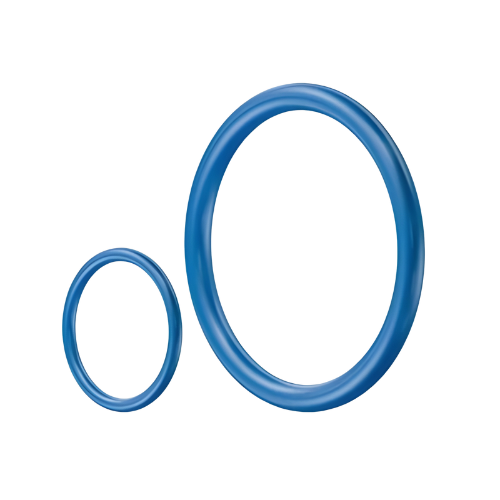

For the most demanding applications, think ammonia, methanol, or synthetic e-fuels, materials such as FFKM Simriz® are indispensable. These elastomers offer near-universal chemical resistance and retain their properties above 300 °C. Seals with such compounds remain stable under extreme conditions. At the same time, RGD-resistant O-rings protect against explosive decompression (Rapid Gas Decompression), a known risk in fuel systems. Through controlled hardness and microstructure, Seals for sustainable fuel engines maintain their integrity even during rapid pressure drop.

Each engine configuration requires a specific validation approach. Seals for sustainable fuel engines are tested against real pressure, temperature, and vibration profiles. Finite Element Analysis and tribological simulations are used to predict how material behaves under cyclic loading. By linking these data to field tests, a reliable picture of wear and permeation emerges. The seals validated in this way offer predictable service lives and lower maintenance costs.

Lower friction directly means lower energy consumption. Therefore, Seals for sustainable fuel engines are designed with surfaces that are both smooth and resilient. Reduced heat generation extends the service life of oil, bearings, and seals. In addition, every leak-free connection helps reduce emissions and minimize fuel losses. In this way, Seals for sustainable fuel engines contribute to the overall efficiency of the powertrain and to the sustainability objectives of the hydrogen economy.

The knowledge gained in compressors, pumps, and fuel cells is now being transferred to engines. Seals for sustainable fuel engines benefit from the same test methods, material formulations, and tolerance strategies. By integrating seals with sensors and smart connectors, maintenance becomes predictable and reliability measurable. In doing so, these seals demonstrate their value in combustion engines as the link between technological innovation and practical sustainability.

EPDM, FKM, and FFKM offer the best balance between chemical resistance and heat resistance. Seals for sustainable fuel engines made from these materials retain their shape and sealing performance at high temperatures.

During rapid pressure drops, internal damage can occur. Seals with RGD resistance prevent cracking and remain leak-free.

They minimize gas diffusion, reduce emissions, and increase efficiency. Low-permeation seals therefore deliver a direct gain in performance.

They are subjected to thermal, pressure, and cycle tests that simulate realistic operating conditions. This proves that Seals for sustainable fuel engines are durable and reliable.