Seals for hydrogen refueling stations play a crucial role in the safety and reliability of the hydrogen infrastructure. From compression to dispensing, all components must operate leak-free at pressures up to 700 bar and in widely varying temperatures. Because hydrogen molecules are extremely small, the risk of leakage and permeation is high. Therefore, every sealing solution requires a carefully tuned material selection, controlled compression, and validation under real-world conditions. Advanced seals are developed and tested to meet these requirements exactly, enabling hydrogen refueling stations worldwide to operate safely, efficiently, and with low maintenance. Seals for hydrogen refueling stations are the crucial link between safety, reliability, and performance in the modern H₂ infrastructure.

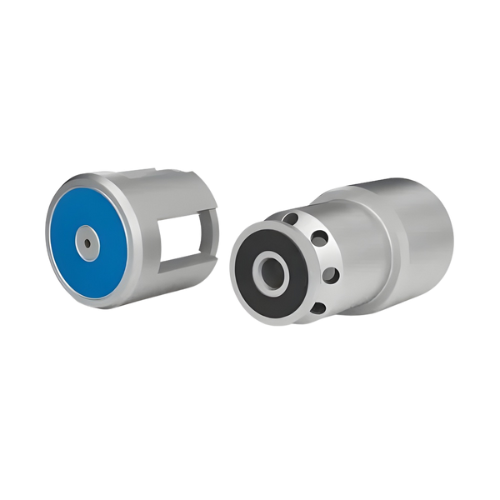

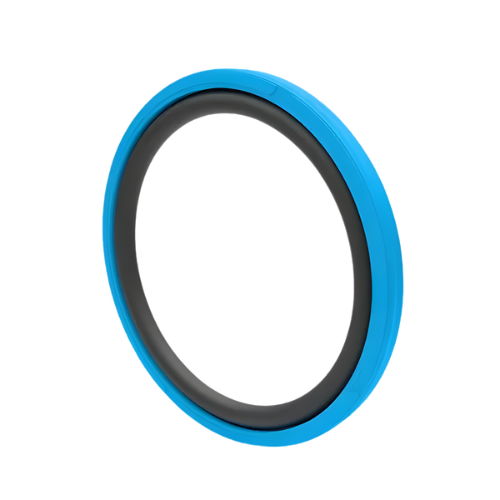

A hydrogen refueling station consists of four main segments: compression, buffer storage, cooling, and dispensing. Each segment contains specific seals that must withstand high pressure, fluctuating temperature, and frequent cycles. In the compressors, low-permeation seals and AED/RGD-resistant O-rings prevent micro-leakage and damage caused by pressure fluctuations. In the buffer storage, PTFE backup rings and static O-rings with high dimensional stability ensure long-term tightness. At the dispensers and couplings, elastomers with controlled compression set provide safe, repeatable connections, even after thousands of refueling cycles.

By investing in high-quality seals for hydrogen refueling stations, leakage at the molecular level can be prevented, even at extremely high pressure.

Hydrogen distribution in refueling stations takes place at pressures of 350 to 700 bar. During refueling, the temperature is often artificially reduced to –40 °C to prevent overheating. These extreme combinations of pressure, temperature and cyclic loading require materials that do not become brittle, deform or allow gas permeation. Seals for hydrogen refueling stations must not only withstand pressure and temperature but also resist vibration, UV radiation and moisture exposure occurring in outdoor installations.

FKM and FFKM offer excellent chemical resistance and low permeation under high pressure. For colder sections and piping systems, EPDM remains preferred due to its flexibility, while silicone is used where elasticity and low compression set are prioritized. Seals for hydrogen refueling stations are designed for continuous operation at 700 bar and must withstand sudden pressure and temperature fluctuations.

The choice of seals for hydrogen refueling stations largely determines the maintenance frequency and overall service life of the dispenser.

Hydrogen is the smallest and most volatile gas molecule in the periodic table. Even minute leakage can lead to energy loss or safety risks. In compressors and dispensers, seals for hydrogen refueling stations ensure that hydrogen is transferred leak-free, clean, and safe. Therefore, low-permeation seals are essential in all parts of the station. By using high-grade fluoroelastomers such as FKM and FFKM, gas diffusion is drastically reduced. The compounds used are tested under real-world pressures, with both microleakage and volume change measured. The result: predictable leak rates at the sccm level and a stable performance profile over thousands of cycles. Modern seals for hydrogen refueling stations combine low gas permeation with excellent chemical resistance, which is essential under long-term hydrogen exposure.

In compressors and valves, pressure drops can occur within milliseconds. Without protection, this can lead to microcracks in the elastomer, a phenomenon known as explosive decompression. Therefore, in hydrogen applications, only AED/RGD-resistant O-rings are used. These compounds are optimized to withstand internal gas entrapment, so the seal remains intact during sudden pressure relief. The result is a longer service life, less downtime, and a higher HSE safety class.

Thanks to the right combination of materials and tolerances, seals for hydrogen refueling stations continue to operate reliably even after thousands of refueling cycles.

The material selection determines not only performance but also the durability of the installation. FKM offers excellent resistance to heat, chemicals, and fuels, while FFKM provides maximum safety in the most aggressive environments. EPDM remains flexible at low temperatures and is resistant to steam and UV, which is ideal for outdoor installations. Silicones are used in static joints and electrical interfaces due to their high purity and dimensional stability. This combination of materials ensures that every segment of the station, from compressor to dispenser, seals optimally regardless of temperature or pressure.

To prevent extrusion at high pressure, PTFE back-up rings are used in combination with O-rings. For designers and installers, seals for hydrogen refueling stations are a critical factor in meeting international safety standards such as ISO 19880. They preserve the shape of the elastomer and limit wear in the groove. By using ISO 3601 groove dimensions, compression remains predictable and repeatable, which facilitates maintenance and inspection. This standardization is essential for global compatibility between suppliers and makes validation easier.

In static joints such as flanges, shut-off valves and valve bodies, seals must retain their elastic force. High-pressure FKM or FFKM O-rings are engineered with a low compression set so they maintain their sealing force after thousands of pressure cycles. In dynamic zones they are combined with supportive PTFE backup rings. This combination guarantees a stable sealing force, even with temperature fluctuations or mechanical vibration. Thanks to innovative compound formulations, seals for hydrogen refueling stations remain elastic for longer and retain their sealing force even under repeated pressure cycling.

Seals for hydrogen refueling stations are extensively tested under realistic conditions. Specialized test facilities simulate pressures up to 700 bar, temperatures from –60 °C to +200 °C, and dynamic loading. Tribological tests measure wear, friction, and heat generation over long cycles. The data are used to feed FEA simulations and further optimize compound formulations. Regular inspection of the seals prevents unplanned downtime and increases the operational safety of the entire dispenser. This ensures that every seal meets the highest safety and performance standards according to ISO 19880 and ISO 3601. When seals for hydrogen refueling stations are correctly validated and installed, emission levels measurably drop below the limit of detection.

For high-pressure zones: FKM or FFKM due to their low permeation and high chemical resistance. In cold and wet sections: EPDM or silicones for flexibility and low compression set.

They prevent extrusion at high pressure and ensure that the O-ring retains its shape, especially at pressures above 500 bar.

They protect seals against microcracking during rapid pressure changes and increase operational reliability.

Standardized grooves guarantee reproducible compression, making seals easy to validate and interchangeable worldwide.