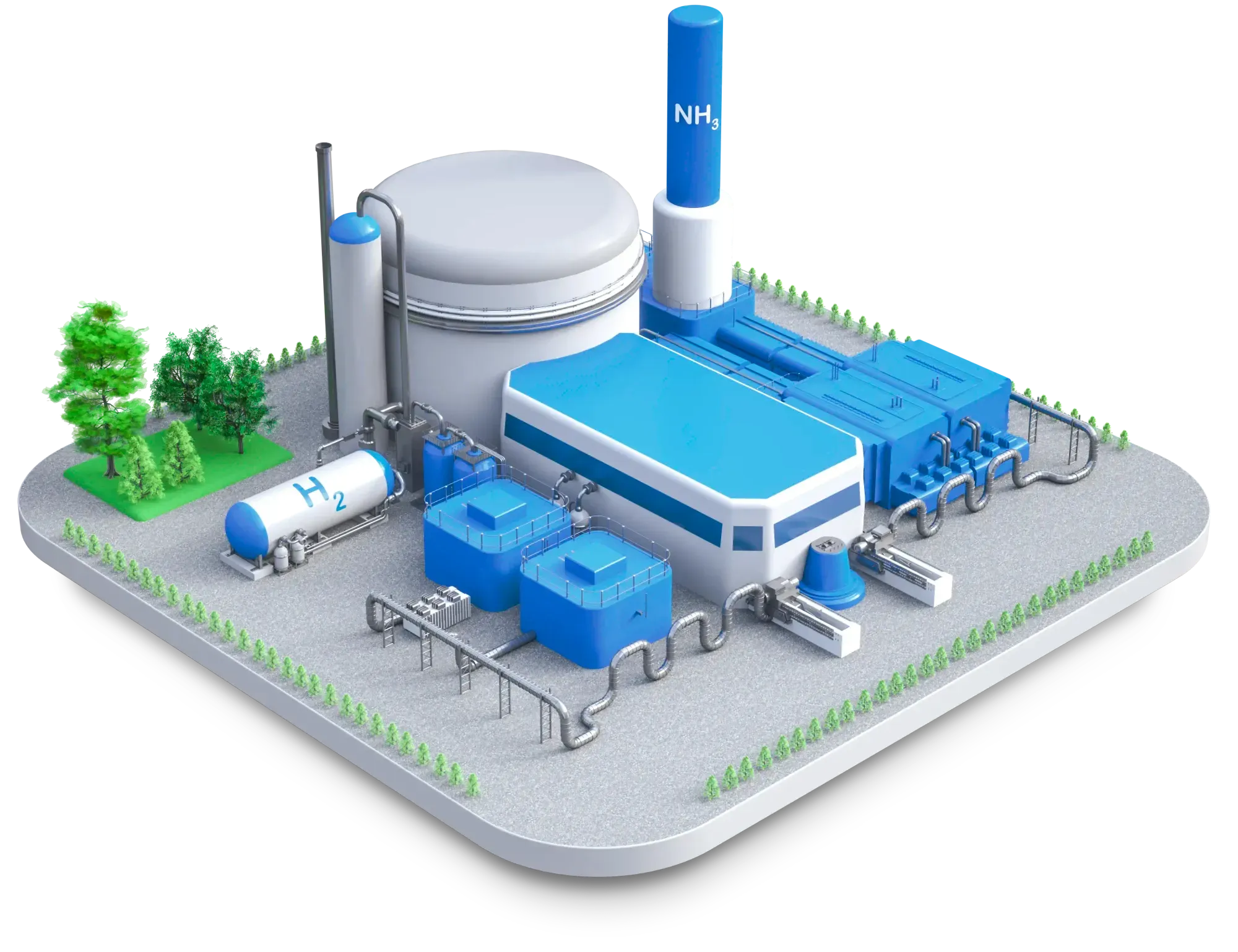

Seals for hydrogen processing must remain reliable under varying pressure, temperature and media. In compression, pump and purification steps, high temperatures, large pressure differentials, hydrogen in gas service and sometimes contaminants come together. Therefore, it’s about low permeation, a stable compression set and predictable behaviour during cyclic operation. With the right combination of product form (O-rings, gaskets, dynamic seals, back-ups and diaphragms) and compound (EPDM, FKM, FFKM, HNBR/AFLAS, PTFE/PEEK), processes become safer and more efficient. Seals for hydrogen processing prove their value when they remain gas-tight even after long-term operation, respect tolerances and allow repeatable assembly. Think of AED/RGD resistance in gas service, tight groove dimensions according to ISO 3601 and traceable batches for QA. By addressing material compatibility, surface roughness and gap width early, you limit microleakage, prevent extrusion and extend service life in every processing step.

Leakage in hydrogen processing is both a safety and environmental issue. Microleakage can go unnoticed due to the small molecular size, while heat sources, moving parts and densely arranged equipment increase the risks. Seals for hydrogen processing with low permeation and controlled compression keep flanges, manifolds, valves, couplings and measurement points gas-tight, even when temperature and pressure vary in cycles. In static joints it comes down to the right groove geometry, surface roughness and bolt preload; in dynamics, friction, wear and heat generation come into play.

In gas service with large pressure differentials, we recommend AED-qualified compounds and PTFE back-up rings to limit extrusion. In this way, seals for hydrogen processing safeguard safety around compressors, pumps, purification trains and utilities, while emissions fall and measurements remain reliable.

Unplanned stops directly cost production, energy and man-hours. Robust seals for hydrogen processing reduce those costs by preventing wear and blow-out, so service intervals become longer and maintenance remains predictable. O-rings with PTFE back-up rings retain shape and seal integrity at large pressure differential; in flanges, appropriate hardness and compression distribution ensure stable leak-tightness. Dynamic sets (rod/piston) with good guidance reduce friction and heat build-up, which limits energy consumption and damage. Result: fewer purge losses and restarts, higher reliability of critical equipment and a lower Total Cost of Ownership. By standardising on groove dimensions (ISO 3601) and compounds, you keep quality and supply consistent from pilot to series—exactly where seals for hydrogen processing make the difference.

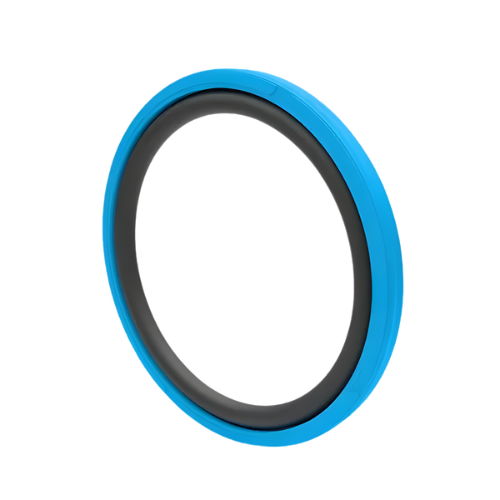

We supply a complete range of seals for hydrogen processing: O-rings and X-rings (static and dynamic), flat gaskets (where sensible also seal-on-frame), rod and piston seals, wipers/scrapers, chevron sets and guide bands. For large pressure differentials and larger gap widths, we deploy PTFE/PEEK back-up rings to prevent extrusion; in pumps and purification steps we supply robust diaphragms. Seals for hydrogen processing require repeatable assembly, uniform compression and minimal variation in sealing pressure. That’s why we support with clear groove guidelines and dimensions, so engineering and production work to the same specifications and validation is completed faster. Where cleanliness matters (analytical measurement points, instrumentation, oxygen lines) we select low-outgassing compounds for more stable measurements and less contamination of sensitive components.

Material selection determines compatibility, service life and safety. EPDM is often logical for water/alkali and utilities; FKM performs well between 150–200 °C and with various chemicals; FFKM pays off for extreme chemistry and heat. For sour service and gas mixes, HNBR or AFLAS are appropriate; PTFE/PEEK provides low friction and dimensional stability and serves as a back-up where gap width or pressure differential is large. Seals for hydrogen processing benefit from compounds with low permeation and a low compression set; in gas service, AED qualification is often advisable. We align with ISO 3601 for groove guidelines and, on request, provide documentation on permeation, compression set and RGD/AED behaviour, so that audits run smoothly and specifications remain consistent from pilot to series.

Compressors in hydrogen processing require seals that can handle large pressure differentials and frequent cycles. O-rings with AED-qualified compounds minimise RGD risk, while PTFE back-up rings limit extrusion. Dynamic sets (rod/piston), wipers and guide bands reduce friction and wear, so sealing integrity is maintained and the service interval is extended. Seals for hydrogen processing in compressors benefit from precise groove dimensions, tight tolerances and good surface finish; this makes performance predictable and maintenance plannable, even when temperature and gas purity vary.

Pumps combine varying pressure with axial/rotational motion and sometimes higher temperatures. Here, seals for hydrogen processing provide stability through appropriate material selection (for example FKM in the 150–200 °C range) and the right guidance to limit tilting and wear. PTFE back-up rings help against extrusion at large pressure differential; wipers keep contamination out, which benefits sealing and service life. With clear guidelines on groove geometry, compression and assembly forces, leak-tightness remains consistent, even after prolonged cyclic operation and varying operating conditions.

Purification and drying stages require clean, stable sealing with low permeation and, where needed, low outgassing. Seals for hydrogen processing in PSA vessels, filters and membrane skids must allow repeatable assembly and withstand pressure swing cycles. EPDM or FKM are often suitable choices depending on medium and temperature; FFKM provides extra assurance with aggressive chemistry. In gas service, AED-qualified compounds limit the risk of internal damage due to rapid decompression, while PTFE/PEEK back-up rings prevent extrusion when gap width or pressure differential increases. Thus performance and measurements remain reliable and predictable.

Roughly: EPDM for water/alkali, FKM around 150–200 °C and various chemicals, FFKM for extreme chemistry/heat; HNBR/AFLAS for sour service; PTFE/PEEK for low friction and back-ups. Always choose based on medium, temperature, pressure differential, cycles and desired service life.

In cases of large pressure differentials, larger gap widths or higher temperatures to prevent extrusion. They stabilise sealing pressure and increase service life, especially in compressors, valves and high-pressure connections.

RGD is damage caused by rapid gas decompression; AED-qualified compounds are more resistant to this. In hydrogen processing with pressure swings, this reduces the risk of internal cracking and loss of leak-tightness.

Work with ISO 3601 groove dimensions, define tolerances and surface finishes, and standardise on compounds. That makes seals for hydrogen processing repeatable, reduces variation and speeds up validation.

Choose compounds with low permeation and ensure correct compression through the right groove geometry and hardness. Pay attention to surface roughness, alignment and assembly forces; consider back-up rings under large pressure differentials to prevent extrusion.