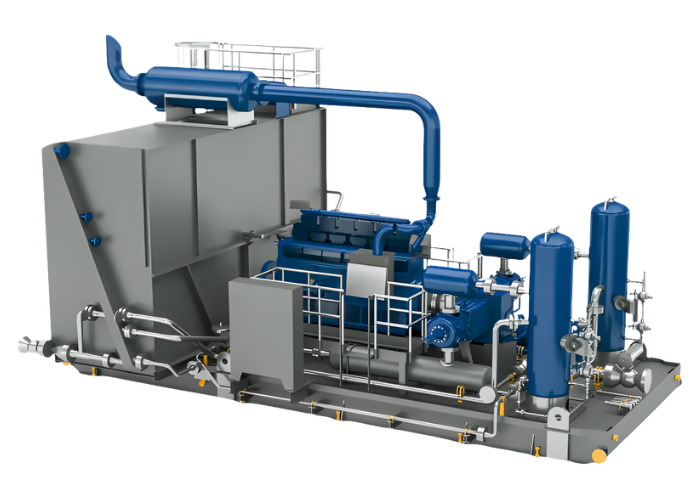

Seals for hydrogen compressors largely determine whether a system runs safely, efficiently and predictably. Hydrogen diffuses quickly, loads in compressors are dynamic (rod/piston), and tolerances are tight, a combination that, without rigorous design and material knowledge, quickly leads to micro-leakage, wear and downtime. Therefore, we look beyond initial leak-tightness: we test behavior after thousands of cycles with varying temperature, vibration and pressure differential. Low permeation, controlled compression and extrusion control (where required with PTFE backup rings) form the foundation. Standardization on ISO 3601 groove sizes makes assembly and measurement repeatable; AED/RGD-resistant O-rings reduce risks during rapid pressure drops in gas service. In applications where contamination is undesirable, oil-free compressor seals help keep measurements and components clean. In this way, seals for hydrogen compressors deliver measurable reliability and a lower TCO.

In dynamic sections it’s about alignment, friction and thermal management. Rod and piston seals retain pressure, while guide bands prevent tilting. Wipers (scrapers) keep contamination out of the cylinder, so surfaces wear less and sealing pressure remains stable. Seals for hydrogen compressors that respond stiff yet elastic perform predictably under frequent cycling and varying gas purity. Match surface roughness and hardness: this keeps film formation healthy and reduces microleakage, even during hot–cold cycles and vibration. Mind clearance and alignment of rod and guidance; side load increases friction, temperature and wear. Ensure consistent lubrication and control stroke speed. With clear tolerances and an appropriate set of wiper/guide/sealing elements, leak-tightness is maintained over the service interval.

In static interfaces, flatness, roughness and bolt preload determine whether the compressive load distribution is uniform. Flange gaskets, seat and stem seals, and coupling O-rings must compensate tolerances without over-compression. Seals for hydrogen compressors that combine low permeation with low compression set limit “weeping” and product loss during temperature fluctuations. In manifolds, O-rings in standardized grooves help achieve measurable, repeatable compression; with larger gap width or high differential pressure, add supporting elements. This keeps leak criteria at the sccm level achievable and makes assembly less sensitive to variation between teams or shifts.

Hydrogen gas service requires seals for hydrogen compressors with demonstrably low permeation, because even microleakage creates safety risks and efficiency losses. Where rapid pressure drops occur (trips, valve actions), an AED/RGD-resistant compound reduces the likelihood of internal damage and premature leakage. Seals for hydrogen compressors that perform on these points contribute directly to HSE objectives and audit robustness. Combine material selection with clear leak criteria and test under identical load profiles as in practice. With that approach, emissions become more predictable, you can plan maintenance, and the risk of costly, unexpected downtime is reduced.

Friction turns into heat; heat accelerates wear and changes material stiffness. Under high differential pressure, extrusion acts as a silent killer: the elastomer is pressed into the gap and loses shape. Seals for hydrogen compressors therefore perform better with proper guidance, clean surface finish and a design that deliberately limits extrusion. Where needed, PTFE backup rings in the grooves prevent the elastomer from extruding into the gap while maintaining sealing pressure. By combining lower friction, controlled heat dissipation and extrusion control, service life increases and leak-tightness remains more stable under cyclic operation.

The toolkit is broad: rod and piston seals, wipers and guide bands for dynamics; O-rings and gaskets for static interfaces; plus supporting elements to ensure dimensional stability. ISO 3601 is the basis for O-ring grooves, so compression and measurement are repeatable across lines and suppliers. With larger gap width or high loads, PTFE backup rings limit extrusion and keep sealing pressure stable. In gas service, choose AED/RGD-resistant O-rings where rapid pressure changes occur; around instrumentation and manifolds, it pays to use low-permeation seals. Where contamination is undesirable, oil-free compressor seals are a safe choice: they minimize contamination, improve measurement reliability and help maintain consistency during long service intervals.

Validation must replicate real-world operation: test candidates in identical grooves, with the same roughness and torque, under the same temperature and pressure profiles as your compressor sees. Measure permeation to make product loss and emissions quantifiable, and record compression set to know whether sealing pressure holds after cycles. Seals for hydrogen compressors deliver predictable uptime when your assembly procedures are standardized and measuring instruments are calibrated. Combine that with condition monitoring (leakage trends, temperature, energy consumption) and you move from reactive to planned maintenance. The result: fewer unplanned stops, clearer service windows and a lower TCO over the life cycle.

Start with task and environment: dynamics call for wear resistance and proper guidance, static zones for low permeation and low compression set. Seals for hydrogen compressors often benefit from EPDM in milder media and from other compounds where temperature or chemistry is more demanding.

When gap width or load can trigger extrusion, for example in high-pressure zones or with larger tolerances. This way, seals for hydrogen compressors remain extrusion-free and maintain their sealing pressure under varying conditions.

Standardized groove sizes make compression and measurement comparable across lines and suppliers. As a result, seals for hydrogen compressors are validated more quickly and are easier to interchange.

During rapid pressure drops in gas service, such as trips or aggressive control actions. Seals for hydrogen compressors with AED properties reduce the risk of internal cracking and premature loss of sealing.

Not necessarily, but in applications where contamination or measurement drift is critical, they are an advantage. Seals for hydrogen compressors without oil contamination help safeguard the reproducibility of data there.