Seals for water splitting may seem like a detail, but they determine whether lab, pilot, and final scale-up run stably and safely. In every phase, water, hydrogen, and oxygen must remain strictly separated while temperature, pH, and pressure profiles vary. That is why it comes down to materials knowledge, design discipline, and measurable validation. Seals for water splitting that combine low permeation with a low compression set and predictable mechanical properties reduce emissions, limit product loss, and increase reproducibility between tests or batches. Add consistent assembly instructions, clearly defined tolerances, and traceable batches, and you reduce the variation that often causes surprises in practice.

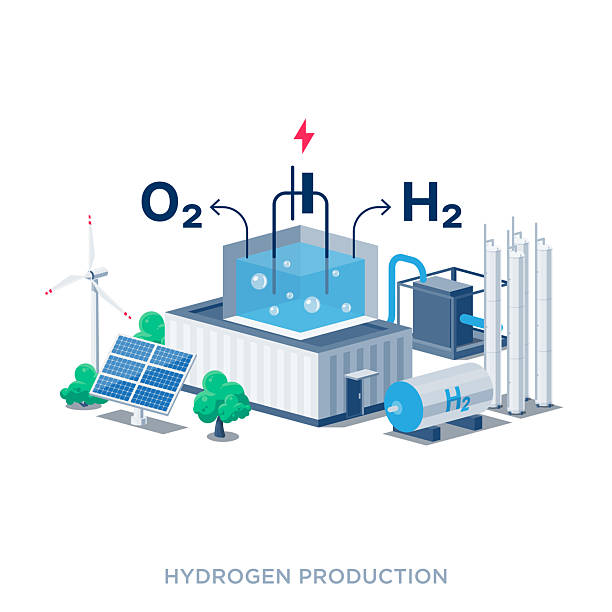

Water splitting is the umbrella term for processes that split water into hydrogen and oxygen using energy from electricity, light, or heat. Think of electrolysis variants, photoelectrochemical (PEC) and photocatalytic routes, plus thermochemical cycles at high temperatures. Each path imposes its own requirements on materials and design. In acidic or alkaline electrolytes, for example, material compatibility changes; in photoprocesses, light/UV and sometimes slurries matter; and in thermochemistry, heat resistance comes to the fore. Seals for water splitting must keep the flows separated in all those contexts without disturbing the hydraulics, and do so in the same way for years, even as test regimes and load profiles shift. This way, Seals for water splitting continue to perform consistently, whether the route is PEC, thermochemical, or electrolysis.

The smallest gas molecule demands sealing discipline: low permeation is the basis to prevent “weeping” and measurement drift. At the same time, you want a uniform compression distribution along the entire sealing line; too little compression causes microleakage, too much can deform channels or shorten service life. Seals for water splitting must also be clean: low outgassing prevents contamination of membranes or sensors. All of this requires choices that go beyond “choosing an O-ring”: roughness, flatness, groove geometry, clamping force, and material quality work together. Those who demonstrably secure this with standards, test reports, and repeatable assembly see fewer failure modes and a more predictable TCO. Robust Seals for water splitting make that balance measurable and repeatable from lab to pilot plant.

Around plates and edges lies the essence: here, compression determines the transition from design to reality. With seal-on-plate or seal-on-frame you can reduce assembly variation and make the compression distribution more uniform, which limits edge leaks and performance drift. In stack-like configurations you want the seal to follow the channel geometry without driving up flow resistance. Seals for water splitting that combine low permeation with controlled hardness and low outgassing keep the cell stable, from first commissioning to long-term endurance testing. Professional teams record clamping force, roughness, and flatness in work instructions and verify them during FAT/SAT, so regression due to manual variation is avoided.

In manifolds, tolerances, pressure fluctuations, and assembly forces come together. O-rings in grooves according to ISO 3601 make compression and measurement repeatable, regardless of line or location. Where gap width or differential pressure creates a risk of extrusion, backup rings or carriers (e.g., PTFE/PEEK) help keep the sealing pressure stable. Seals for water splitting in these zones must also withstand varying lubrication states and vibration, especially with frequent connecting/disconnecting or with fast-acting valves. It pays to define leak criteria per interface at the sccm level, so you can objectively assess whether assembly or material adjustments have an effect and whether you are audit-ready in practice.

Beyond geometry, documentation matters. Standardize on a limited number of hardnesses and compounds to make inventory and maintenance predictable, and define tightening torques and sequences to prevent uneven loading. Seals for water splitting perform noticeably better when you specify batch purity and post-cure/cleaning, especially near sensors and membranes. Also consider galvanic pairs and grounding/insulation requirements: a well-chosen seal can prevent electrical breakdown without compromising chemistry or mechanics. Finally, calibrate instruments that monitor compression and torque; otherwise your process capability is a guess. Standardized Seals for water splitting in ISO 3601 grooves reduce the chance of errors and speed up validation.

Chemistry and temperature steer the shortlist. EPDM is often logical in water/alkali and cooling-circuit-like environments, with a neat balance between elastic recovery and low compression set. At 150–200 °C and with more diverse chemicals, FKM comes into view; FFKM offers additional margin with aggressive media or higher temperature. In interfaces where dimensional stability and low friction are needed, PTFE/PEEK elements provide support or limit extrusion. Seals for water splitting also benefit from low permeation, especially when long operating periods and strict leak criteria apply. By tying material selection to real cycles in the test protocol, you limit surprises during scale-up and ensure that datasheets and reality align. The right Seals for water splitting, often EPDM or FKM/FFKM, follow the chemistry rather than the other way around.

Design is your quality lever. With ISO 3601 groove dimensions you fix compression and interchangeability; this makes rejects traceable and speeds up validation. Roughness and flatness have a direct impact on edge leaks and service life, so define them unambiguously and verify them during incoming inspection or pre-assembly checks. Seals for water splitting must then be tested against relevant profiles: permeation (to quantify product loss and emissions), compression set (for sustained sealing pressure), and, where necessary, outgassing (for sensor and membrane integrity). Apply cycles and temperatures that your route actually sees; generic tests are seldom predictive and often lead to costly lessons in the field.

Start with chemistry and temperature: EPDM in water/alkali, FKM at 150–200 °C and with more diverse chemicals, FFKM for aggressive media or higher temperature. Link the choice to targets for low permeation and the desired service life.

Because they standardize compression and measurement. This makes results comparable across lines and suppliers, and lets you validate more quickly whether changes to Seals for water splitting really have an effect.

They are useful when gap width or the pressure profile induces extrusion, or when you want to stabilize sealing pressure under dynamic conditions. Backup rings/carriers (e.g., PTFE/PEEK) offload the elastomer and increase the predictability of Seals for water splitting.

Use low-outgassing compounds, specify cleaning/post-cure, and avoid aggressive lubricants near sensors and membranes. This keeps signal and calibration stable. That is why many teams choose Seals for water splitting with controlled outgassing as the standard near sensors.