Shaft seals for powder are heavily loaded in industrial installations. In applications where dry powders and granulates are processed, such as screw conveyors and bulk-handling systems, abrasive particles and the absence of lubrication often lead to rapid wear and leakage. Standard shaft seals are usually not designed for these conditions. To solve this problem, special shaft seals for dry powders have been developed, which provide reliable sealing without oil or grease. In this article, we explain why powder is so critical for seals, how a specialized sealing concept such as PUFO works, and which technical and normative aspects must be taken into account.

- Why shaft seals for powder require a separate approach

- Shaft seals for powder: the PUFO sealing concept

- Design and material selection for sealing dry media

- Standards and tolerances for shaft seals in powder applications

- Shaft seals for powder in food applications and FDA compliance

- Applications in screw conveyors and bulk handling

- FAQ

Powder and granulate behave fundamentally differently from liquids. In dry media, the lubricating film for which conventional shaft seals are designed is absent. At the same time, fine particles act as an abrasive on the sealing lip and the shaft running surface. Due to rotation, vibrations and pressure differences, powders also easily migrate along minimal clearances, causing dust leakage to occur quickly.

This makes shaft seals for powder technically demanding. In installations where milk powder, cocoa, coffee, spices, pharmaceutical powders, minerals or chemicals are processed, standard shaft seals often fail prematurely. They wear quickly, lose their sealing function and cause contamination, downtime and additional maintenance.

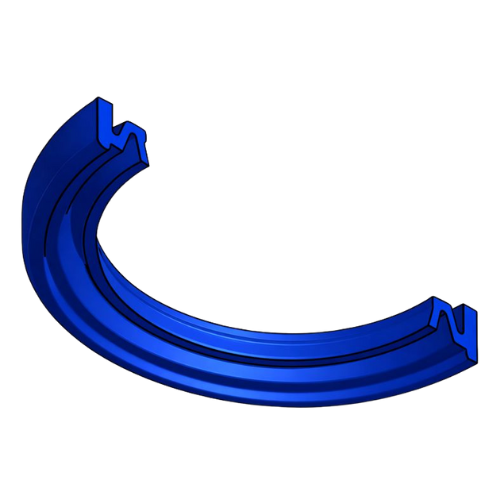

For this type of application, Freudenberg has developed a specific sealing concept tailored for dry operation: PUFO (PolyUrethane For dry Operation). This is not a standard shaft seal, but a purpose-designed radial shaft seal for powder and granulate.

The PUFO concept focuses on excluding dust and powder without relying on oil or grease. The seal operates with a specific lip geometry that applies a controlled contact pressure on the shaft. As a result, the seal remains dust-tight while friction and heat generation are kept to a minimum. This makes PUFO particularly suitable as a shaft seal for dry media and abrasive powders.

An important distinguishing element in shaft seals for powder is the choice of material. PUFO seals are made of polyurethane, a material characterized by high wear resistance, good tear resistance and stable behavior under dry friction. Compared to classical elastomers, polyurethane retains its shape and sealing force better during prolonged exposure to fine and hard particles.

In addition, the design is adapted to typical operating conditions in powder applications. Screw conveyors and dosing screws often operate under variable loads, start-stop cycles and slight axial movements. A shaft seal for powder must be able to follow this dynamic behavior without the sealing line becoming unstable, which significantly reduces the risk of dust leakage.

For shaft seals for dry powders, standards and tolerances are directly decisive for service life. Because no lubricating film is present, deviations in dimensions or surface roughness are not compensated. Radial shaft seals are basically aligned with ISO 6194, which defines the functional principles for shaft seals.

The fit between shaft and seal is usually defined in accordance with ISO 286, with combinations such as H10 for the housing bore and f9 for the shaft. For the shaft surface, a fine ground finish according to ISO 1302 applies in order to limit wear and dust build-up. General dimensional tolerances fall under DIN ISO 2768, while geometrical tolerances are assessed according to DIN ISO 1101. The hardness of the shaft is specified according to ISO 6508 (Rockwell HRC) and is essential for abrasive powder flows.

In the food industry, shaft seals for powder are widely used in installations where products such as milk powder, cocoa, coffee, tea and spices are processed. In these environments, not only sealing performance is important, but also the suitability of the material used for contact with food.

For food applications, shaft seals for powder are available in FDA-compliant materials that meet the requirements of FDA 21 CFR for materials intended for contact with food. For polyurethane seals, this means that specific compounds are used that are suitable for application in food processing installations, within defined temperature and application limits.

Because these shaft seals are designed for dry operation, they function without oil or grease. This prevents the risk of product contamination by lubricants and contributes to a hygienic process design. Therefore, FDA-compliant shaft seals for powder are a logical choice for applications in the food industry where reliability, wear resistance and food safety come together.

The advantages of specialized shaft seals for powder are particularly evident in screw conveyors and other bulk-handling installations. In these applications, they provide reliable sealing, reduced dust leakage and longer maintenance intervals.

For sectors such as food, pharmaceutical and chemical industries, this results in higher process reliability and a lower total cost of ownership. Shaft seals for powder that are specifically designed for dry and abrasive media therefore form an essential component of a stable and safe installation.

Standard shaft seals are designed for lubricated applications and wear quickly when used with dry and abrasive media. Shaft seals for powder are specifically developed for dry operation and prevent dust leakage without relying on oil or grease.

Shaft seals for powder are widely used in screw conveyors, dosing screws and other bulk-handling installations. They are mainly found in the food, pharmaceutical and chemical industries where dry powders and granulates are processed.

Yes, for food applications, shaft seals for powder are available in FDA-compliant materials. This makes them suitable for use in installations where direct or indirect contact with food may occur.