14 results

| Item no. | Inner diameter (dM) | Outer diameter (DM) | Material | Design | Stock | Price | |||

|---|---|---|---|---|---|---|---|---|---|

|

|

49317381 | 8.2 | 16.9 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49317386 | 16.2 | 33.9 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49348036 | 16.9 | 29.6 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49380410 | 4.2 | 9.7 | FLUOROPRENE | 316 | € 11,62 | Details | ||

|

|

49380416 | 8.2 | 16.9 | FLUOROPRENE | 688 | € 15,37 | Details | ||

|

|

49380417 | 10.2 | 21.2 | FLUOROPRENE | 998 | € 17,85 | Details | ||

|

|

49380419 | 16.2 | 33.9 | FLUOROPRENE | 317 | € 28,06 | Details | ||

|

|

49392455 | 16.2 | 33.9 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49392456 | 12.2 | 25.5 | EPDM | ? | € 11,46 | Details | Quotation | |

|

|

49392457 | 10.2 | 21.2 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49392458 | 8.2 | 16.9 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49392459 | 6.2 | 13.1 | EPDM | ? |

On request

|

Details | Quotation | |

|

|

49392480 | 5.2 | 10.7 | EPDM | ? | € 7,12 | Details | Quotation | |

|

|

49392481 | 4.2 | 9.7 | EPDM | ? |

On request

|

Details | Quotation |

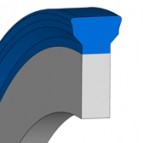

USIT A HY USIT Rings are engineered to deliver effective static sealing solutions with a focus on hygiene and reliability. These seals are designed to meet EHEDG standards and ensure dead space-free sealing in or near product areas, preventing the formation of microfilms and corrosion. The seal material options include 75 Fluoroprene® XP 45 (Blue), 70 EPDM 253815 (white), and 70 EPDM 291 (black), providing flexibility for various applications.

These hygienic USIT rings are especially well-suited for applications in the food and beverage and pharmaceutical industries where hygiene and purity are of paramount importance. The design of these seals prevents the accumulation of microorganisms and particles, making them ideal for sealing in open processes with direct media contact. The metal ring material, 1.4404, ensures durability and reliability in challenging environments.

When using USIT A HY USIT Rings, it's crucial to adhere to the recommended guidelines for optimal performance. The seal's lip geometry has been optimized for use with specific screws and cap nuts for flange connections based on DIN EN 1665. Proper installation and adherence to the recommended tightening torques are essential to prevent damage to the seal. It's important to ensure that the components are in contact before the Hygienic Usit® is installed to avoid potential damage due to sliding between the screw head and the seal. Ultimately, thorough testing in the actual field application is recommended to validate the ring's performance in the specific customer context.

USIT A HY USIT Rings provide a reliable and hygienic sealing solution for industries with stringent hygiene requirements. Their design, material selection, and EHEDG compliance make them a valuable component in applications where cleanliness and sealing integrity are critical.