8 results

| Item no. | Inner diameter (dM) | Outer diameter (DM) | Shore Hardness | Material | Stock | Price | |||

|---|---|---|---|---|---|---|---|---|---|

|

|

3007638 | 21.54 | 28.58 | 85 Shore A | NBR | ? |

On request

|

Details | Quotation |

|

|

49305912 | 3.8 | 6 | 70 Shore A | NBR | 7671 | € 5,10 | Details | |

|

|

49305921 | 10.7 | 16 | 70 Shore A | NBR | 13673 | € 5,36 | Details | |

|

|

49322497 | 8.7 | 14 | 70 Shore A | NBR | 14699 | € 5,10 | Details | |

|

|

49327812 | 7.4 | 10 | 70 Shore A | NBR | 200 | € 1,94 | Details | |

|

|

49376341 | 5.4 | 8 | 70 Shore A | NBR | 4798 | € 1,94 | Details | |

|

|

49376342 | 5.8 | 9 | 70 Shore A | NBR | 5780 | € 1,94 | Details | |

|

|

49379214 | 75 Shore A | FKM | 964 | € 1,94 | Details |

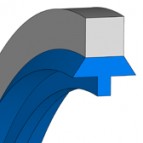

When it comes to static sealing in various industrial applications, the USIT I SF USIT Rings stand out as a top-tier choice. These rings boast a robust metal packing equipped with a vulcanized, trapezoidal, rubber-elastic sealing bead, available in both internal (U) and external (UA) variations. This innovative design ensures a secure and self-reinforced seal, making them ideal for a range of sealing needs.

One of the key advantages of the USIT I SF USIT Rings is their hassle-free assembly. The rings' design allows for easy installation, minimizing downtime and optimizing workflow efficiency. Additionally, these rings offer force fit connections, enhancing their reliability and longevity even in demanding environments. Their ability to withstand high pressures further underlines their suitability for critical applications where maintaining a consistent and secure seal is of utmost importance.

The applications of USIT I SF USIT Rings span across various industries, with a significant focus on mechanical engineering. These rings find their role in sealing threaded fittings and flange connections, particularly in scenarios where dependable static sealing is required. Whether in heavy machinery or precision equipment, these rings deliver the performance and durability needed to ensure leak-free operations, ultimately contributing to the overall reliability and longevity of mechanical systems.

In conclusion, the USIT I SF USIT Rings present an innovative solution for static sealing needs. With their trapezoidal rubber-elastic sealing bead, easy assembly, force fit connections, and high-pressure suitability, these rings offer unmatched reliability in sealing threaded fittings and flange connections. As a versatile choice for applications in mechanical engineering and beyond, these rings play a pivotal role in enhancing the performance and longevity of industrial systems.