Freudenberg Sealing Technologies (FST) announced on 24 September 2025 that it will present its latest e-mobility solutions at The Battery Show North America 2025. The trade fair will take place from 6 to 9 October 2025 at Huntington Place in Detroit, USA. Visitors can find FST at booth #5208, where the focus will be on components and sealing solutions designed to improve the efficiency, reliability, and functionality of both current and next-generation vehicles.

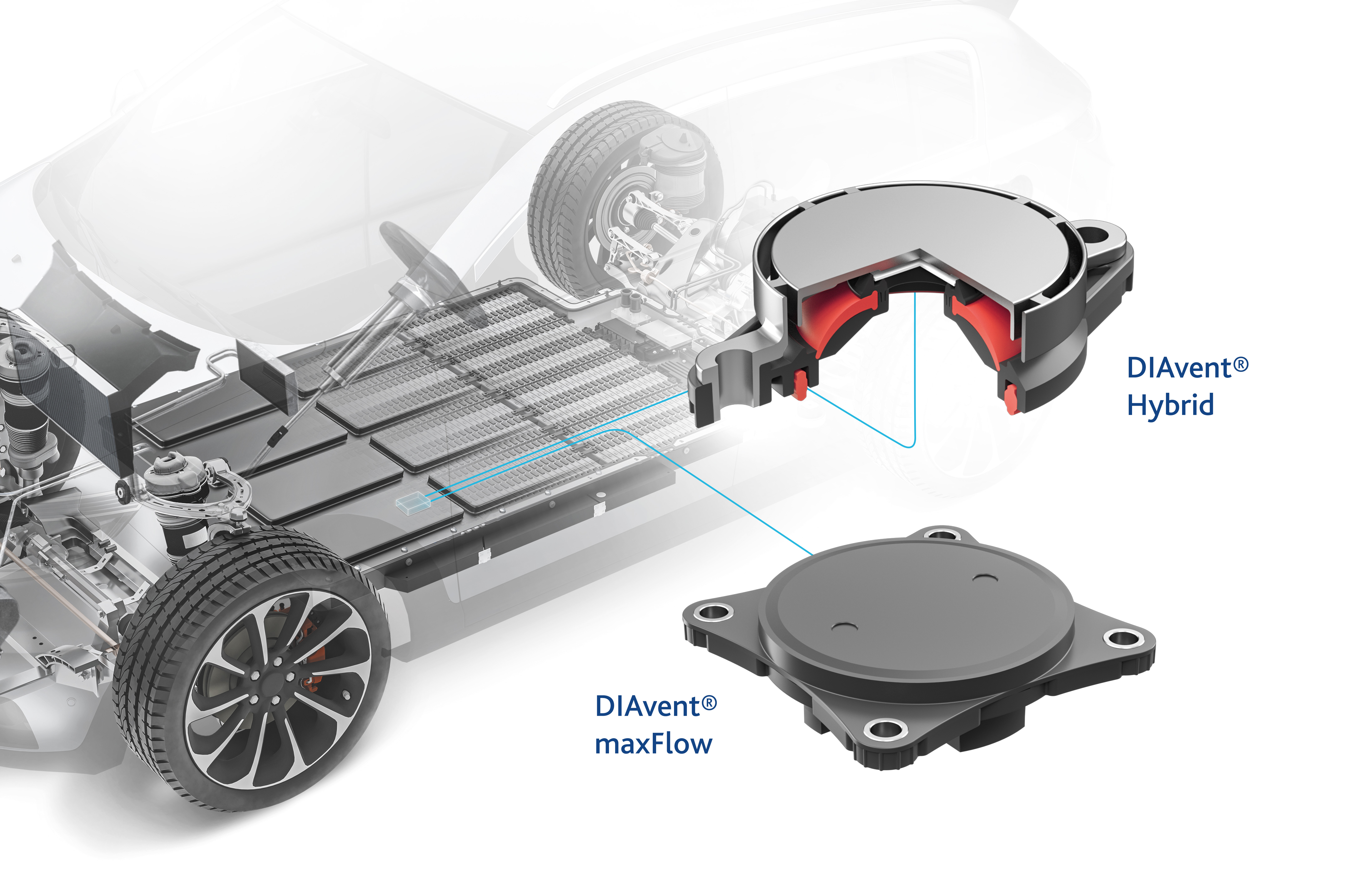

A key theme at the booth is pressure management in lithium-ion battery packs. For safety and performance, battery enclosures need to remain sealed as effectively as possible, while also requiring controlled pressure equalization and emergency venting. To address this, FST is showcasing its DIAvent® portfolio: a (patented) product family for pressure equalization during normal operation, supplemented with emergency degassing functions. According to the press release, the portfolio includes variants for compact battery systems as well as higher-capacity versions for larger, energy-intensive vehicles, plus applications for components such as e-motors, axles, and inverters.

FST also reports two expansions driven by customer demand. The DIAvent® maxFlow is designed with an open degassing vent (instead of opening gradually), which, according to FST, makes the full degassing rate available around the opening pressure. The activation level can be set between 50 and 200 mbar. The second addition is the DIAvent® Hybrid, which combines permanent bidirectional pressure equalization with emergency degassing and also offers the option to mount the aluminum cover directly and securely to the battery enclosure. Both are intended for high-energy-density battery systems.

In addition to pressure management, FST is highlighting a sealing solution for busbars—the conductors that enable energy transfer in battery systems. In practice, busbars are difficult to seal properly due to geometric variations and exposure to aggressive media and temperature fluctuations. To address this, FST is presenting a media-tight busbar sealing technology suitable for both rectangular and round busbars. In the press release, FST states that the solution can eliminate additional assembly steps and reduce leakage risk, with a temperature range of -40 °C to 200 °C and improved resistance to thermal cycling and aggressive media.

As EV batteries grow larger and charging speeds increase, thermal management becomes increasingly critical. FST is therefore showcasing fluid connectors designed for a wide range of coolants and thermodynamic requirements, with the aim of improving cell temperature control and supporting battery lifetime. The press release also notes that the connectors can combine functions and compensate for tolerances to simplify assembly. In addition, FST is presenting solenoid valves that regulate air and fluid flows in automotive and battery systems by converting electrical signals into controlled mechanical movement.

Tania Hagel (Global Vice President, OEM Sales) summarizes the positioning with the message that customers need “agile and experienced partners” who can quickly deliver optimized materials and technologies when new challenges arise.

FST is bringing other solutions to Detroit as well, including a 3D Waveguide Antenna for radar systems (ADAS and autonomous driving), as well as battery cell caps, housing gaskets, and a thermal barrier demonstrator. The press release adds that SurTec Group and Freudenberg Filtration Technologies will also be represented at the same booth.

Source: Freudenberg Sealing Technologies press release, “Solving Today’s Challenges to Power Tomorrow’s Mobility”, 24 September 2025 (text provided by user).