23 results

| Item no. | Nominal volume (V) | max. Load | Width (b) | Outer diameter (D) | Internal thread fluid port (IG) | Material | Design | Stock | Price | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

49315593 | 0,08 l | 250 Bar | 118 | 64 | G 1/2 (F) | ECO | DACC | 27 | € 158,31 | Details | |

|

|

37003913 | 0,16 l | 250 Bar | 126 | 75 | G 1/2 (F) | NBR | DACC | 21 | € 107,82 | Details | |

|

|

37004553 | 0,32 l | 210 Bar | 140.5 | 92 | G 1/2 (F) | NBR | DACC | 30 | € 137,31 | Details | |

|

|

37004555 | 0,32 l | 210 Bar | 140.5 | 92 | G 1/2 (F) | ECO | DACC | 19 | € 205,37 | Details | |

|

|

49315980 | 0,50 l | 210 Bar | 170 | 106.7 | G1/2 (M33) | ECO | DACC | 25 | € 217,91 | Details | |

|

|

37005085 | 0,50 l | 210 Bar | 159 | 106.7 | G 1/2 (F) | NBR | DACC | 32 | € 171,24 | Details | |

|

|

49362861 | 0,60 l | 330 Bar | 189 | 110 | G1/2 (M33) | NBR | DACC | 20 | € 267,77 | Details | |

|

|

37005717 | 0,75 l | 210 Bar | 173 | 121.5 | G 1/2 (F) | NBR | DACC | 23 | € 187,85 | Details | |

|

|

37005718 | 0,75 l | 210 Bar | 173 | 121.5 | G 1/2 (F) | ECO | DACC | 18 | € 191,52 | Details | |

|

|

37005719 | 0,75 l | 210 Bar | 184 | 121.5 | G1/2 (M33) | NBR | DACC | 29 | € 158,55 | Details | |

|

|

49334111 | 0,75 l | 350 Bar | 180 | 128.5 | G 1/2 (F) | NBR | DACC | 24 | € 231,76 | Details | |

|

|

49362287 | 0,75 l | 350 Bar | 191 | 128.5 | G1/2 (M33) | NBR | DACC | 26 | € 274,56 | Details | |

|

|

49362518 | 0,75 l | 350 Bar | 191 | 128.5 | G1/2 (M33) | ECO | DACC | 31 | € 363,12 | Details | |

|

|

49319918 | 1,00 l | 210 Bar | 187 | 136.2 | G 1/2 (F) | NBR | DACC | 22 | € 244,97 | Details | |

|

|

37006227 | 1,00 l | 210 Bar | 187 | 136.2 | G1/2 (M33) | ECO | DACC | 28 | € 316,13 | Details | |

|

|

37006524 | 1,40 l | 250 Bar | 202 | 152 | G 1/2 (F) | NBR | DACC | 21 | € 357,53 | Details | |

|

|

49359159 | 1,4 l | 250 Bar | 202 | 152 | G 1/2 (F) | ECO | DACC | 30 | € 297,70 | Details | |

|

|

49333012 | 1,4 l | 250 Bar | 213 | 152 | G1/2 (M33) | NBR | DACC | 19 | € 367,07 | Details | |

|

|

49386805 | 1,4 l | 250 Bar | 213 | 152 | G1/2 (M33) | ECO | DACC | 27 | € 381,26 | Details | |

|

|

49362011 | 2 l | 350 Bar | 255 | 156 | G 3/4 (F) | NBR | DACC | 25 | € 622,54 | Details | |

|

|

37006896 | 2 l | 250 Bar | 255 | 156 | G 3/4 (F) | ECO | DACC | 20 | € 608,50 | Details | |

|

|

49380956 | 2.8 l | 250 Bar | 289 | 169 | G 3/4 (F) | ECO | DACC | 23 | € 507,47 | Details | |

|

|

49344117 | 3,5 l | 250 Bar | 316 | 169 | G 3/4 (F) | ECO | DACC | 29 | € 617,27 | Details |

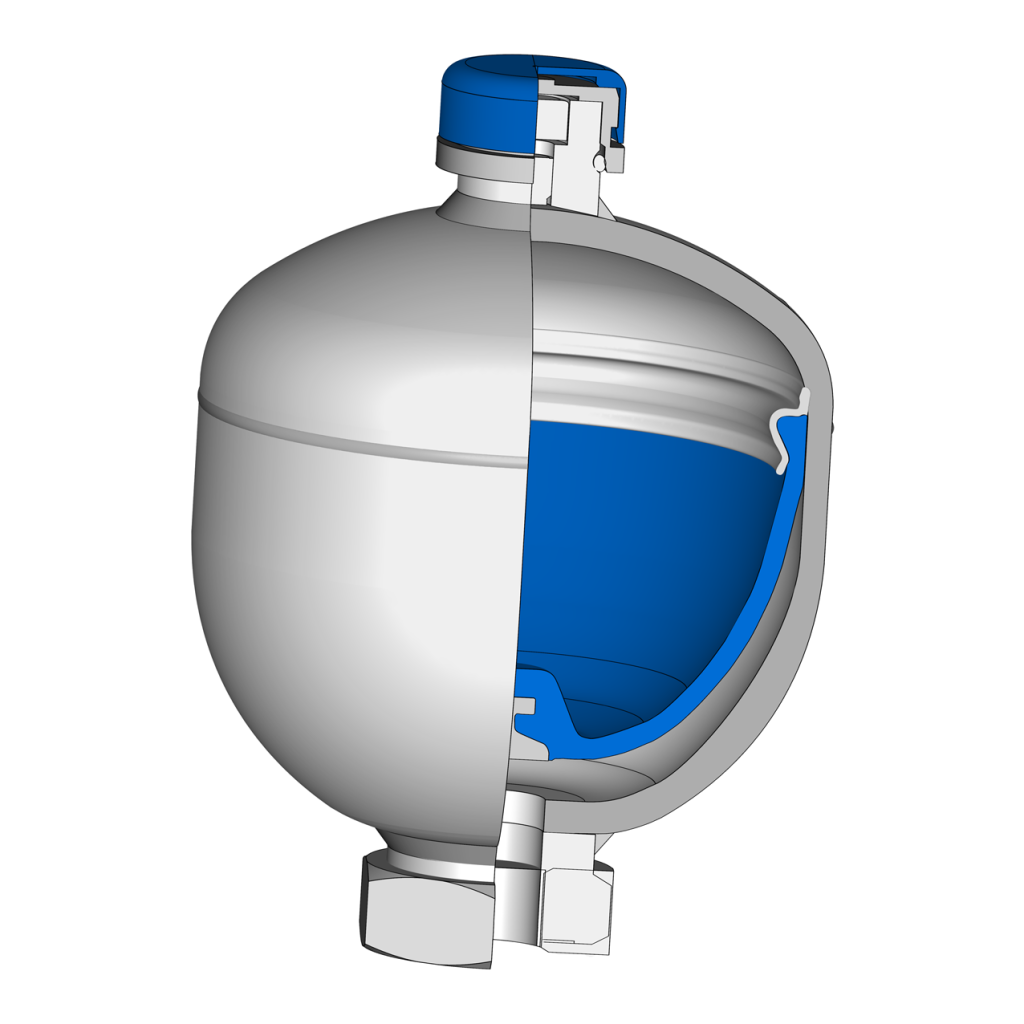

A diaphragm accumulator is a type of hydraulic accumulator consisting of a welded steel housing with an internal diaphragm. This diaphragm separates the gas side—usually filled with nitrogen—from the fluid side, which is connected to the hydraulic system. When system pressure rises, the diaphragm is compressed and the accumulator stores energy in the form of compressed gas. When system pressure drops, the accumulator releases this stored energy back to the fluid side.

Thanks to this mechanism, diaphragm accumulators can absorb peak loads in a hydraulic system, compensate for pressure fluctuations, and dampen pulsations. The DACC accumulators are an ideal solution for compact applications and systems that require a fast and reliable response to pressure changes. Their simple construction makes them low-maintenance and well-suited for various industrial and mobile hydraulic systems.

Diaphragm accumulators offer several advantages that make them particularly suitable for modern hydraulic systems. Their compact design allows for easy installation, even in applications where space is limited. The fully welded steel housing, combined with a rubber diaphragm, ensures a reliable separation between the nitrogen and hydraulic fluids, resulting in consistent performance.

Diaphragm accumulators can operate across a wide temperature range and are available with either NBR or ECO diaphragms. Accumulators with an NBR diaphragm can be used in temperatures from -20°C to +80°C, while ECO diaphragms are suitable for conditions ranging from -40°C to +80°C. Moreover, DACC diaphragm accumulators from Freudenberg Sealing Technologies comply with the European PED directive, making them a safe and durable solution for both industrial and mobile applications.

Thanks to their compact construction, DACC diaphragm accumulators are easy to integrate into both mobile and industrial hydraulic systems. They take up little space and are lightweight, simplifying installation. For secure mounting, an optional accumulator clamp is available to keep the unit firmly in place. The welded steel housing ensures long-term reliability. Additionally, the sealed design and durable materials make DACC diaphragm accumulators low-maintenance—ideal for applications where space, simplicity, and performance are key for an efficient hydraulic system.

Standard DACC diaphragm accumulators are equipped with NBR (nitrile rubber) diaphragms, suitable for use from -20°C to +80°C. For applications requiring a wider range, ECO (epichlorohydrin rubber) diaphragms are available, allowing use from -40°C to +80°C. With both material options available, DACC accumulators can be used in a wide variety of environments and applications.

Diaphragm accumulators stand out for their high dynamic load capacity and long service life. Compared to bladder and piston accumulators, diaphragm accumulators offer a more compact design with fewer moving parts—reducing wear and minimizing the risk of leakage. The robust steel housing, durable elastomers, and low gas diffusion ensure reliable operation even under intense use. With their fast response time, low maintenance needs, and internal check valves that enhance safety, diaphragm accumulators are the ideal solution for systems with frequent pressure variations.

Diaphragm accumulators are used across various sectors due to their versatility, compact design, and reliable performance. The DACC diaphragm accumulators play a vital role in hydraulic systems where energy storage, pressure control, and shock absorption are required. Examples include industrial machinery like excavators, articulated dumpers, or mobile installations. With broad connectivity options, they can be tailored to specific applications and environmental conditions. From automation to agriculture and from forklifts to machine tools, diaphragm accumulators improve performance, efficiency, safety, and comfort.

Freudenberg Sealing Technologies’ diaphragm accumulators offer a wide range of technical configurations that can be precisely tailored to various hydraulic applications. The standard series are developed in accordance with the European PED directive. These DACC accumulators are available in volumes from 0.07 L to 3.5 L and are suitable for applications with a maximum operating pressure of up to 350 bar.

Various connection types and diaphragm materials provide a broad scope of application possibilities. The compact design and low maintenance requirements make these accumulators especially well-suited for integration into existing hydraulic systems.

The standard DACC diaphragm accumulators from Freudenberg Sealing Technologies are designed for continuous operating pressures of up to 350 bar. They are available in a range of volumes, starting at 0.07 L and going up to 3.5 L, making them suitable for both small and large hydraulic systems. This variation allows for precise selection based on energy storage, pressure stabilization, or pulsation absorption needs. For systems with higher pressure peaks or larger oil volumes, models with higher flow capacities are also available.

Want to know which volume/pressure combination fits your system? Read our blog for detailed guidelines and calculation examples.

Determining the correct size for your DACC diaphragm accumulator is essential for optimal system performance. It’s important to consider the system’s minimum and maximum pressures, the desired oil volume, and the accumulator’s function. Using Boyle’s Law, you can calculate the required nitrogen volume and what percentage of the accumulator’s volume must be available for hydraulic fluid.

Visit our blog for a step-by-step explanation of how to perform these calculations.

When selecting a DACC diaphragm accumulator, it’s important to check if it has the correct connections and precharge settings for your system. Depending on your setup, you can choose male or female threads such as G1/2, M28x1.5, or UNF variants. In addition, the nitrogen precharge pressure plays a vital role in proper accumulator function. The correct precharge value depends on the application: for energy storage, the precharge should be set to 90% of system pressure; for shock absorption, it should be 95%.

Our blog includes a step-by-step guide on how to set the correct precharge for your specific application.

Looking to order a diaphragm accumulator? At Sealing Technologies, you benefit from fast delivery, tailored technical advice, and a wide selection of high-quality DACC diaphragm accumulators. Our products meet the European PED directive and are available from stock in various volumes and pressure ranges. With our specialized knowledge, we help you choose the right configuration for your application. Whether you're active in industry, agriculture, or mobile hydraulics—Sealing Technologies is your go-to partner for ordering your diaphragm accumulator.